Olds Elevator Design and Operating Characteristics

The basic principle of the Olds Elevator is very simple, however it is a whole new science opening up new possibilities.

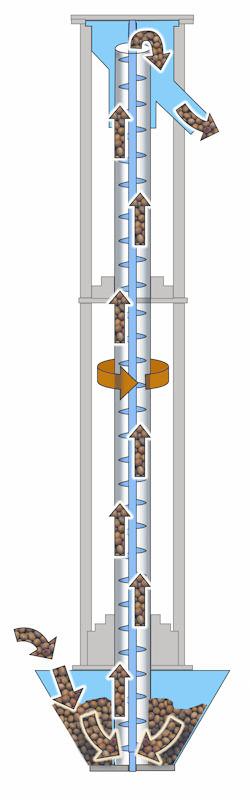

The design has only one moving part in contact with the bulk material, a tubular casing with attached in-feed scoops that rotates around a static screw. Generous clearance is provided between the static screw and casing. This clearance is an important design feature that prevents damage to the bulk material, casing wear and metal-on-metal contact.

The elevator is self-feeding at a controlled rate as it rotates. Bulk material in the feed hopper typically covers the in-feed scoops. Friction against the inner wall of the casing rotates the material and causes product resting on the screw flight to be driven gently up the inclined face of the screw.

The full-bore flow of material avoids back-flow or "leakage" of material through the annular clearance, and hence improves "transport" (operational) efficiency. This also helps to stabilise the central position of the screw to inhibit casing contact, and contrasts dramatically with the dynamic "leakage" that takes place in a conventional screw elevator that offers little resistance to the whirling potential of the rotating screw.

Transport efficiency is increased further by the lower slip between the particles and screw flight surface (i.e. compared with a conventional vertical screw conveyor).

Provides inherent protection against dust explosions

Due to its full-bore mode of flow, the Olds Elevator also provides an inherent explosion barrier or choke that will prevent explosions or deflagrations propagating to other parts of the plant. It also avoids the high-risk ignition sources that can occur inside conventional elevators, especially bucket elevators.

|

|

Smooth and precise delivery rates

The in-feed scoops provide a positive, controlled input of material that is volumetrically proportional to casing speed. Hence, the machine can be used as a feed-rate controller, whereas other elevators work as conveyors only and generally need to be fed by another piece of equipment that has to be matched with the loading of the elevator.

Furthermore, the Olds Elevator can be operated over an extremely wide range of rotational speeds and hence, turn-down ratios. Also, the flow of material through and from the Olds Elevator is always smooth and steady, without the pulsations experienced with conventional screw conveyors and bucket elevators. This steady mode of flow is gentle to the product and hence, minimises particle damage and dust generation (even when handling fragile particles).

Hygienic and easy to clean

The bottom bearing and shaft seal (necessary in a conventional screw elevator) are eliminated. Bearings are not in close proximity with the agitated product. Dust and valuable plant space are minimised. At all points, bearings are totally external to the product flow and accessible for maintenance, if required.

With no seals or bearings at the discharge, the elevator is well suited to handling difficult hot, abrasive or corrosive bulk materials.

The invention is finding wide applications including the Food and Agricultural industries, Clean Coal Industry, Nuclear Power Industry, Mining, Military, and diverse processing industries.

Olds are building a worldwide "family" of licensees for this emerging technology with superior levels of safety and efficiency.

|